HygiSeal 3.1

Description

HygiSeal 3.1 is the new product for chemical welding of joints with a 1K hybrid polymer.

Cleanrooms, laboratories, production areas, wet rooms, packaging areas, kitchens, etc... are subject to intense daily use and intensive cleaning. These area's must comply with the highest standards of hygiene. PolySto HygiSeal is an isocyanate-free and durable sealant solution that meets up to the requirement!

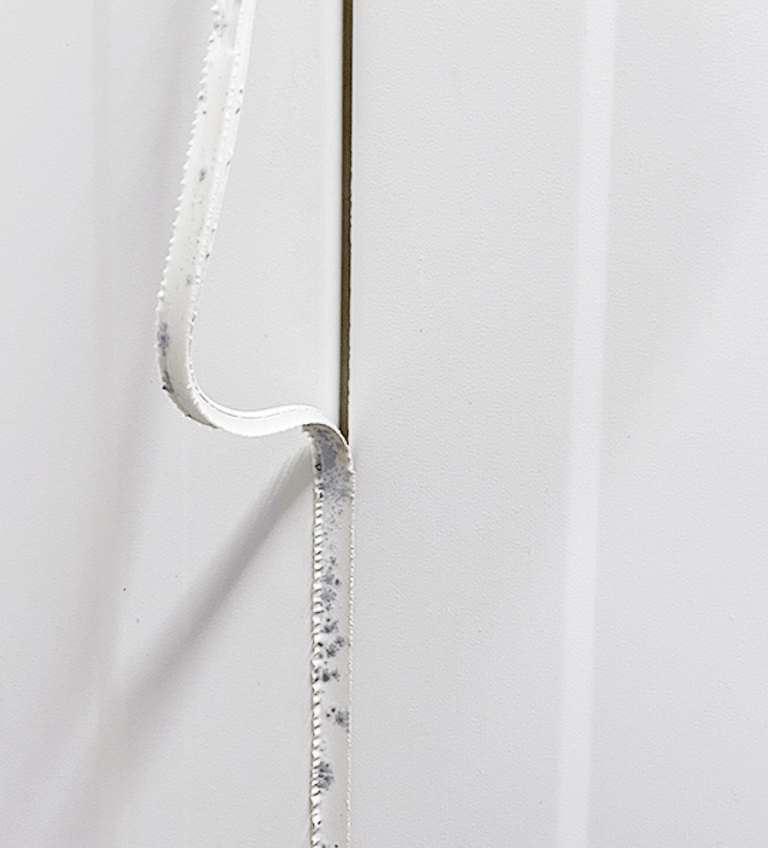

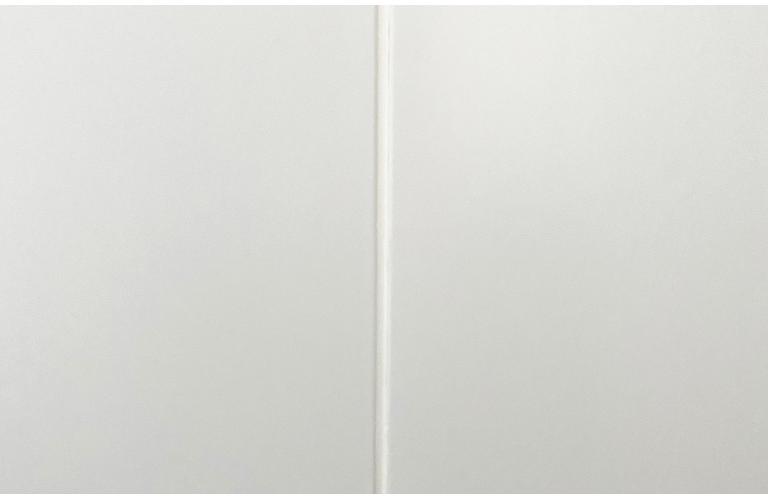

The chemical welded HygiSeal joint between the PolySto components and the connection with floor and wall ensure a durable, seamless and fungus repellent connection that is resistant to intensive high pressure cleaning.

Due to the hard and smooth surface of HygiSeal joints there is less bacterial adhesion compared to classical food safe silicones.

Hygiseal is tested and certified for VOC standards as BREEAM Nor and International; Indoor Air Comfort; French A+ "Emissions dans l'air intérieur" and Italian CAM Edilizia.

HygiSeal 3.1 can be delivered in three different colours to suit a range of design preferences and applications. HygiSeal is available in bags of 600cc (20oz).

What are the problems with classic sealants in the food industry?

Silicone joints are commonly used in construction and manufacturing industries to provide a flexible and waterproof seal between two surfaces. However, the use of silicone joints in food-safe environments is not recommended, and it's important to understand why.

The primary concern with using silicone joints in food-safe environments is the potential for contamination. Silicone is a porous material that can absorb and trap bacteria, making it difficult to clean and sanitize. This is particularly problematic in environments where food is being prepared or stored, as the bacteria can easily transfer to the food, leading to foodborne illnesses.

In addition to the potential for bacterial contamination, silicone joints can also degrade over time, releasing harmful chemicals that can leach into the food. This is especially true in high-temperature environments, where the silicone can break down and release volatile organic compounds (VOCs) that are harmful to human health.

To avoid these issues, it is important to use food-grade materials that are specifically designed for use in food-safe environments.

HygiSeal, a total hygienic design solution

HygiSeal 3.1 is a 1-component, Food safe, chemical welding joint system which offers key advantages for food safe environments:

-

Non-porous: HygiSeal 3.1 creates a seamless, non-porous joint that is impervious to liquids, making it ideal for use in food safe environments where hygiene is paramount. The absence of gaps or spaces means that bacteria and other contaminants cannot accumulate, reducing the risk of foodborne illnesses.

-

Easy to clean: The smooth, non-porous surface of the chemical welding joint is easy to clean and sanitize, helping to maintain a high level of hygiene in food safe environments. There are no gaps or spaces for food particles, dirt, or other debris to accumulate, making it easier to keep the area clean and reduce the risk of contamination.

-

Chemical resistance: HygiSeal creates a strong, durable bond that is resistant to a wide range of chemicals. This makes them ideal for use in food processing and storage areas, where harsh chemicals may be used for cleaning and sanitation purposes.

-

High strength: The HygiSeal joint is able to withstand a significant amount of force without breaking or becoming damaged, ensuring a long-lasting, reliable solution for food safe environments.

-

Wide application temperature: HygiSeal can be applied in enviroment temperatures from 5°C to 35°C. When fully cured, HygiSeal can withstand temperatures up to 90°C.

-

Versatility: HygiSeal can be used to create a seamless, hygienic seal between a wide range of surfaces, including walls, floors, ceilings, windows, doors and much more. This makes it a versatile solution for a variety of food safe applications, from food processing and storage areas to commercial kitchens, restaurants and CleanRoom / laboratories.

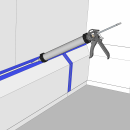

Easy to install

The installation of HygiSeal does not require any special tools or equipment. A standard 600cc (20 oz) caulking tool does the job. HygiSeal is designed to be dispersed using a manual, pneumatic or battery driven caulking gun.

HygiSeal is resistant to high pressure cleaning!

HygiSeal is constructed from a unique, high-strength polymer that is engineered to be highly resistant to impact, abrasion, and chemicals. This means that it can withstand the force of high-pressure cleaning systems without cracking, chipping, or deteriorating over time.

HygiSeal can be used to finish sandwich panels

Sandwich panels are often used in the construction of food processing environments, cleanrooms and other controlled surroundings, where they are used to create walls and ceilings that are both strong and lightweight. HygiSeal can be used to seal the joints between these panels, creating a seamless and smooth surface that is easy to clean and maintain.